achi e vers ne v er exp o se themse l ves

- Engineering

Make a Homemade Homework Writing Machine

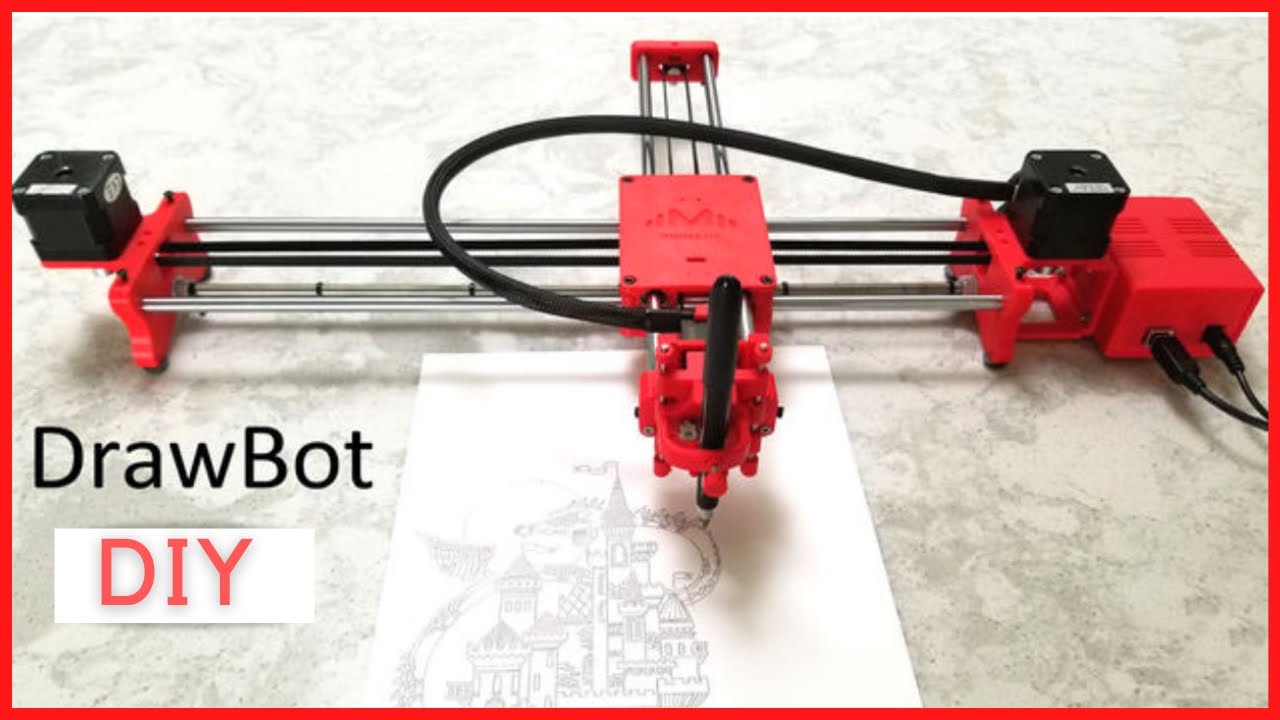

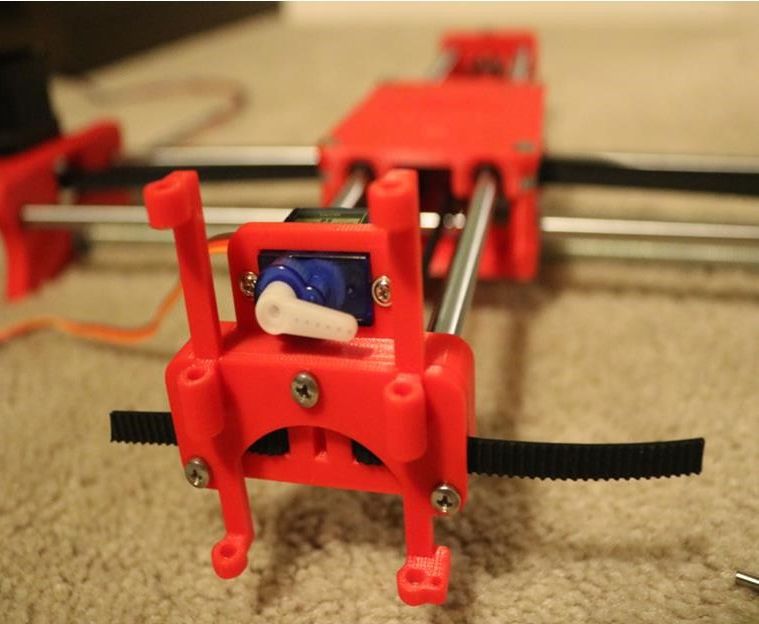

Drawing Robot/Pen Plotter/Drawing Machine is an Open Hardware version of the well-known AxiDraw pen plotter.

Drawing Robot/Pen Plotter/Drawing Machine is an Open Hardware version of the well-known AxiDraw pen plotter, which can write or draw on nearly any flat surface.

It can handle a wide range of applications by writing with pens, permanent markers, pencils, and other writing utensils.

Its one-of-a-kind design includes a writing head that extends outside the machine, allowing it to draw on items that are larger than the machine.

Because of the machine’s core XY extending design, it can be put over the book, which is its major benefit.

This Drawing Robot/Pen Plotter/Drawing Machine looks a lot like the AxiDraw, which is a commercially available product.

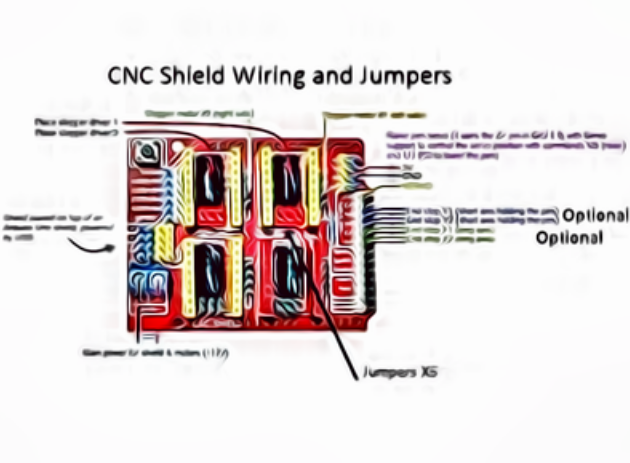

It’s controlled by an Arduino Uno, has a CNC Shield, and runs on GRBL firmware.

The cost of building the Drawing Robot varies between $75 and $150, depending on where you buy your parts and whether you already have some, such as the Arduino.

24 * 30 cm is the maximum sketching area.

Step 1: Gather the necessary parts and materials

Nema 17 stepper motors (two) 2 × M8 x 450mm Linear Rods for X Axis 2 × M8 x 350mm Linear Rods for Y Axis 2 x 3mm Linear Rods for the Z Axis (you can get it from old CDROM) 1 × Threaded Rod M8 x 480mm8 x LM8UU Bearings 1 x Sg901 x Spring 5m Servo (from ball point pen) 2 x GT2 Pulley, 16 teeth Bearing 624zz (Set of 5) 1 × 2000mm GT2 belt 1 × Arduino Uno 1 x CNC Shield 2 x A4988 stepper drivers, each with its own heatsink 6 x Jumpers 1 × 12V 2A Power Supply

M3-0.5 x M4-0.7 x M3-0.5 x M4-0.7 x M3-0.5 x M4-0.7 18 x 4 x 5/16in

Amazon\sScrews

13 × M3-0.5 x 16mm Phillips 4 pcs M3-0.5 x 6mm Phillips 5 pcs M4-0.7x 35mm Phillips 1 × M3-0.5 x 20mm Hex Washers washer, 4 x 5/16in M3 washers (four)

Step 2: 3D Printing

Thingiverse is where you can get the files.

Cura or another slicer may be used to open the 3D models.

Use a 75 percent infill on all portions (a 70 to 100 percent infill would suffice).

All pieces were printed with a layer height of 0.10–0.20 mm.

PLA was used to print this.

Use the Penholder, Slider, X Support L, and X Support R as supports.

Note: The longest component took around 10 hours to print, while the shortest took only 30 minutes.

PLA is suitable for this project.

On BuildTak, I print at 200°C.

There are no rafts or brims required for any of the sections.

Only the pen holder and the upright Z axis end plate should be supported, in my opinion.

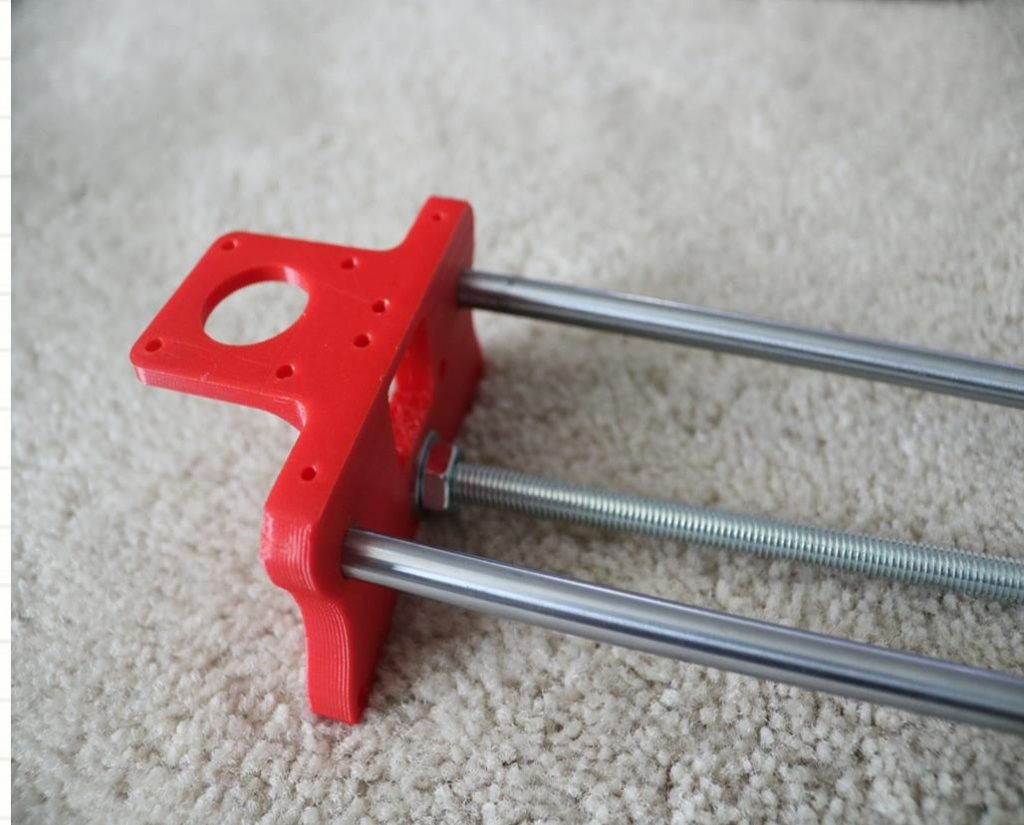

Step 3: Put the X-Axis together

Keep in mind that you’ll need two 350mm and two 450mm linear rods.

Insert the (2) 450mm linear rods into one of the x-support parts.

You may need to smooth up the holes with a round file before inserting the rods. You may also use a rubber mallet to assist insert the rods.

The threaded rod should now be inserted into the hole below.

On both sides of the x-support section, feed a 5/16in washer and 5/16in nut.

Step 4: Put the X-Axis Bearing Together

Slide the clamshell through the 450mm linear rods (X-axis).

Attach the final X-support on the linear rods with a rubber mallet once again.

Make sure the rods are evenly spaced on both sides.

Thread the opposite end of the threaded rod through the X-hole. support’s To keep the X-support in place, add the last set of nuts and washers.

You may now add (2) Phillips M3-0.5 x 16mm screws per X-support to assist keep the linear rods from slipping now that the X-axis is complete.

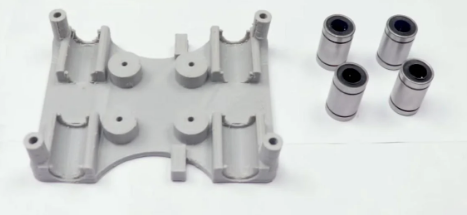

Now you must push the LM8UU bearings into their proper positions on the top and bottom clamshells (each clamshell requires four bearings).

Push four 624zz bearings through the idler pulleys that were 3D-printed. When assembling the Y-axis, save the fifth bearing for later.

Construct the X-Axis (Carriage)

With the idler pulleys fitted, get (4) M3-0.5 x 20mm screws, (4) M3 nuts, (4) M3 washers, and (4) 624zz bearings.

Feed a washer through one screw; the washer will rest on the bearing.

The bearing will be secured in place by a nut at the bottom of the carriage.

You may now use (2) Phillips M3-0.5 x 16mm screws to complete the X-axis.

each X-support, screws to protect the linear rods from slipping

Step 5: Put the Y-Axis together

Using a rubber mallet, insert the (2) 350mm linear rods into the Y-back piece.

Obtain one M4-0.5 x 35 screw, one M4 nut, and the fifth 624zz bearing.

To fasten the linear rods, get two M3-0.5 x 16 screws.

When screwing the Y-back piece together, slide the bearing in.

Slide the linear rods/Y-back piece through the LM8UU bearings and use a rubber mallet to secure the Y-front piece.

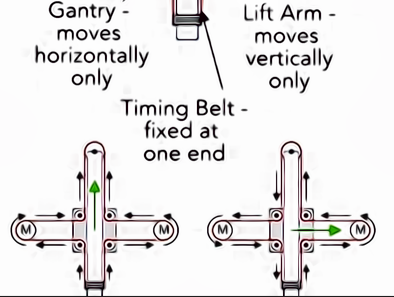

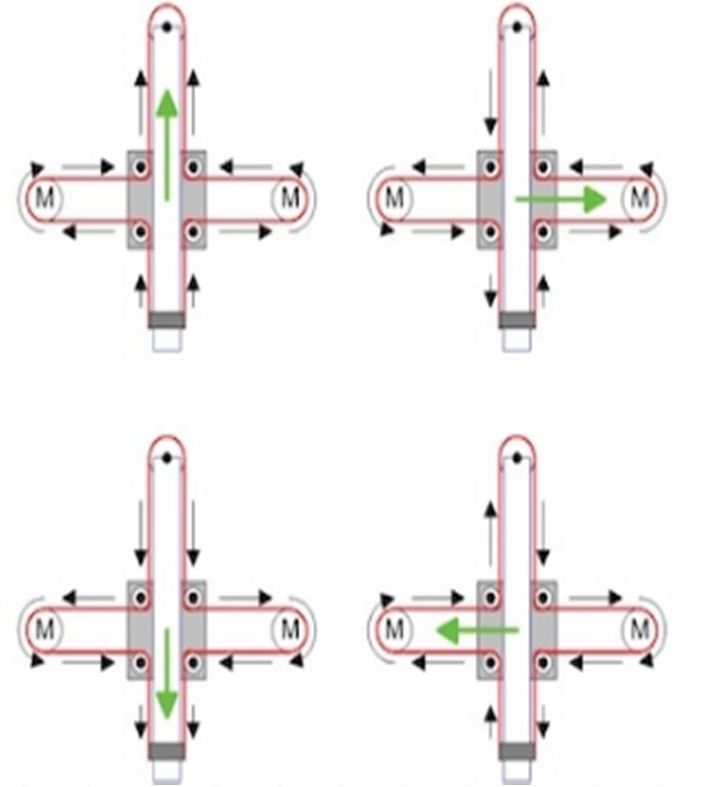

Step 6: Put the X-Y Axis Together (Belt)

To make it easier to guide the GT2 belt through the clamshell, use a set of needle nose pliers.

Take the two ends of the belt and thread them through the Base Slider’s “teeth.”

The belt should be snug, not slack.

It is common for the clamshell to not move freely after the GT2 belt is installed.

Step 7: Put the Z-Axis together.

2 3mm linear rods and the 3D printed items listed below (Slider, Pen Holder, Base Slide, 3MM Metric Thumb Screw)

Take one Hex M3-0.5 x 20mm screw and one Metric Thumb Screw and combine them.

To hold things together, use superglue.

You’ll need three M3-0.5 x 16mm screws to fasten the Base Slide to the Y-Front portion.

To keep it in place, you might need to use three M3-0.5 nuts.

To make one piece, push the Slider and Pen Holder together.

Step 8: ELECTRONICS

ELECTRONICS

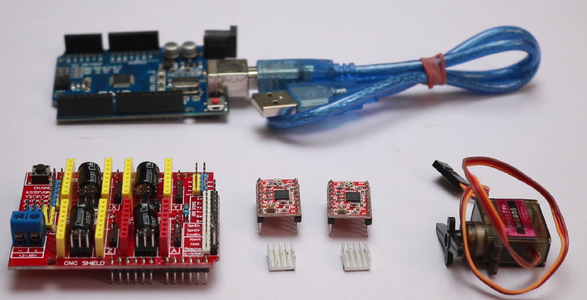

I recommend that you utilise the Arduino uno CNC Shield.

Prepared for your whole circuit

1) A4988 Stepper Motor Driver, 4 pcs 2) A4988 Expansion Board Driver 3)Arduino UNO (Arduino Uno)

To begin, take the hit sink and place it on the A4988 motor driver.

Attach four A4988 stepper motor drivers to the A4988 driver module on the extension board, then connect the arduino to the expansion board and connect all wire.

The shield also includes built-in micro stepping control, which means that instead of utilising full or half steps like a huge CNC, we can have the motors move by 1/16 or 1/32 of a step to move the laser with the greatest accuracy.

The motors, on the other hand, will use more electricity and become hotter more quickly.

Short several of the mode pins together to use the micro stepping modes.

Various combinations result in various resolutions.

Take a look at the diagram to see the many combinations that are available.

After the shield has been configured, connect the A4988 drivers and the rest of the electronics.

Use a multimeter to locate the stepper motor coils.

You have a coil if there is resistance between the two wires.

The coils are represented on the diagram by two wires of the same colour.

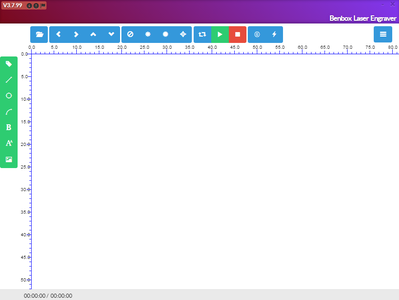

Step 9: APPLICATION SOFTWARE

Inkscape is a graphics design software programme (draw or import graphics)

MI GRBL Extension for Inkscape (convert graphics to G-Code)

G Code Sender (Universal) (sends the G-Code to the robot causing drawing motion)

The Arduino firmware is GRBL (programmed into the Arduino Uno)

Be Confident, Have Positive Gesture, Convincing Body Language, Disciplined Actions, Dedicated Approach, Be Determined, Be Transparent KP

“Update your mindset with time to improve your growth and business, Have a timely pivot” – KP

Helping Hands

About the author

pondabrothers

You can download our apps and books for free.. Search - Incognito Inventions

Ik was op zoek naar dit project van lange tijd, ik ben je echt dankbaar heel erg bedankt 🙂

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- Artificial Intelligence

- Data Science

- Ethical Hacking

DIY Homework Writing Machine

by akashv44 in Circuits > Robots

29249 Views, 348 Favorites, 0 Comments

In this Instructable, I'll show you how to create a completely functional 3D-printed writing machine for your science fair project at school or college. This project was created as part of my second-year engineering project at Gujarat's Chandubhai S. Patel Institute of Technology (CSPIT). I also make this video for my YouTube channel "Creativity Buzz".

To design this writing instrument, I used Autodesk Fusion 360. There are many different kinds of writing robots, but in this lesson, I create a corexy writing machine. Making use of this will teach you everything there is to know about this writing robot.

All of the 3D printed parts are attached stages in the .stl file. You can download this and edit it in Autodesk Fusion 360 as necessary.

There are three types of products need to make this Writing Machine.

1) Electrical Materials

2) Hardware Materials

3) Software and Firmware

- 3D Printer https://3dflyingbear.com/

- Arduino Uno (1 pc) https://amzn.to/3GtBDFT

- CNC Shield V3 Expansion board (1 pc) https://amzn.to/3GtBDFT

- A4988 Stepper Motor Driver (2 pcs) https://amzn.to/3GtBDFT

- Nema 17 Stepper Motor ( 2 pcs) https://amzn.to/3KjIoeN

- SG90 Servo Motor (1 pc ) https://amzn.to/3ZU7arD

- 12 Volt 2 A Adapter

- 2 pin Short Jumper ( 6 pcs )

- 8 mm Threaded Rod 42 cm long and Nut (2 pcs)

- 8 mm Plain Steel Rod 35 cm long (2 pcs)

- 8 mm Plain Steel Rod 27.5 cm long (2 pcs)

- 6mm Plain Steel Rod 6.5 cm long (2 pcs)

- 7mm Spring @ 20 Rs (1 pc)

- LM8UU Slider bearing (8 pcs) https://amzn.to/3KnvtIP

- LM6UU Slider bearing (2 pcs) https://amzn.to/40TpjHk

- 623ZZ 10x4x3 mm bearing (10 pcs)

- Stepper motor Pulley GT2 (2 pcs)

- GT2 6mm Belt 2 meter https://amzn.to/3ZWBTEp

- 3mm + Nut and Bolt ( 16mm , 40 mm length )

3) Software

- Autodesk Fusion 360 ( We use this software to design 3d .stl parts to use in 3d printer to make plastic parts )https://www.autodesk.in/products/fusion-360/

- Ultimate cura ( We use this software for slice .stl file to gcode for use in 3d printer ) https://ultimaker.com/software/ultimaker-cura/

- Arduino IDE ( For Install corexy Firmware to Arduino Uno ) https://www.arduino.cc/en/software

- Inkscape version 0.92 ( For make gcode file for writing or drawing or photo to use in universal gcode sender) https://inkscape.org/release/inkscape-0.92/?latest=1

- Universal gcode sender ( Import gcode file which exported from Inkscape and give command to writing machine) https://winder.github.io/ugs_website/download/

Make Plastic Parts

We design plastic parts in Autodesk Fusion 360 and export them as .stl files. All .stl files that are attached to steps that use them. Import the stl files into the ultimaker cura slicer software and adjust the settings for the walls and nozzles you require.

Then, export the gcode file to a memory card and print it using PLA filament on a 3D printer. Make every 3D printed object step by step. To assemble this writing machine, we need 10 3D-printed components. The total weight is around 250 grammes.

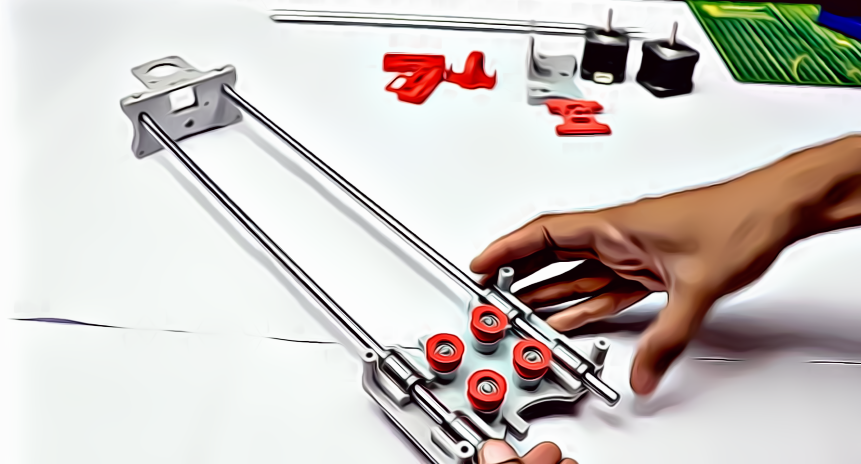

Make Y Axis Slider

Take two 42 cm long 8 mm threaded rods, 8 mm nuts, and the stepper motor holder after all the 3D-printed parts have been completed printing. Then, as shown in the picture, passing this threaded road from the bottom holes in the stepper motor holder. Next, insert threaded rods from the opposite end of the second stepper motor holder.

Fix two nuts on the second end of the threaded rods after passing them through both stepper motor holders.

Added Stepper Motors

Next, take two stepper motors and insert them into the stepper motor holders' casing. Then tighten every screw on the holder joint and stepper motor.

Take two 8 mm plain steel rods that are 35 cm long and pass them through the stepper motor holder's top holes.

If you need to write on a huge scale, you can use long steel rods, although large highways reduce the quality of your writing.

Middle Slider for the X- Axis and Y-axes

After creating the y axis, create the middle slider that connects the x and y axes.

Take two middle slider plastic 3d printed parts for this, one additional 3d printed part, LM8UU Slider bearing (8 pieces), 623ZZ 10x4x3 mm bearing (8 pieces), and 40mm x 3mm bolts and nuts.

Place one 3D-printed slider object four LM8UU Slider bearings, and Attaché the other 3D-printed slider object four LM8UU Slider bearings. Next, insert four 40mm long bolts into the holes shown in the illustration. From the other side, attach two 623ZZ bearings to these bolts. Then attach all bolts from the opposite side and attach the middle 3D-printed part to the other middle part. Then secure the middle slider with the final four 40mm bolts.

After creating the middle slider, take the Y axis and remove half of the plain rod, and run the middle slider through this. After that, reattach the plain rods to the stepper motor holder.

The pen holder needs to be built once the Y-axis has been constructed.

Two 6.5 cm long 6mm plain steel rods, two LM6UU slider bearings, and a 7mm spring are the components you'll need to assemble a penholder using 3D printed materials. As shown in the picture, place two LM6UU bearings into the two holes in the grey 3D printed portion. Then, using two 6 mm plain rods, pass them through the wooden 3D-printed components of the pen holder as shown in the third picture. Place a 7 mm spring between the holder and bearing for the second rod while passing the first rod directly.

Use 16-mm bolts and nuts to attach the red pen stand to the grey 3D-printed portion.

Make X Axis

Two 27.5 cm long 8 mm plain steel rods, a pen holder, and a 3D printed belt end portion are required to make the X axis.

Attach two 8mm steel rods to the belt end 3D printed item as shown in the picture. After that, move the Y axis' middle slider over this structure. Fix the pen holder to the second end of the steel rod after that. Fix a permanent junction with two 16mm bolts.

Pulley and Roller

Then insert two 623ZZ bearings into the pen holder and fix them using a 40-mm bolt.

Get two GT2 stepper motor pulleys and attach each one individually to the stepper motor shaft.

Run GT2 Belt

Take a 2-meter GT2 belt and attach one end to the wooden belt holder portion that was 3D printed.

Next, pass the second end of the GT2 belt through the 623ZZ bearing on the middle slider, the stepper motor GT2 pulley, the 623ZZ bearing on the pen holder, the GT2 pulley, and the 623ZZ bearing on the middle slider before attaching the second end to the belt holder 3D printed component as shown in the pictures.

Make Controller Box

Arduino Uno, CNC Shield V3 Expansion board, two A4988 Stepper Motor Driver, and six short jumpers are required to create the controller box.

Take a controller box that was 3D printed and mount an Arduino Uno on it. On the Arduino Uno, attach the CNC Shield V3 Expansion board as shown in the picture. Then, as shown in the diagram, take a short jumper and place it on the CNC shield. Place the final two A4988 drivers into the CNC mill as shown in the illustration.

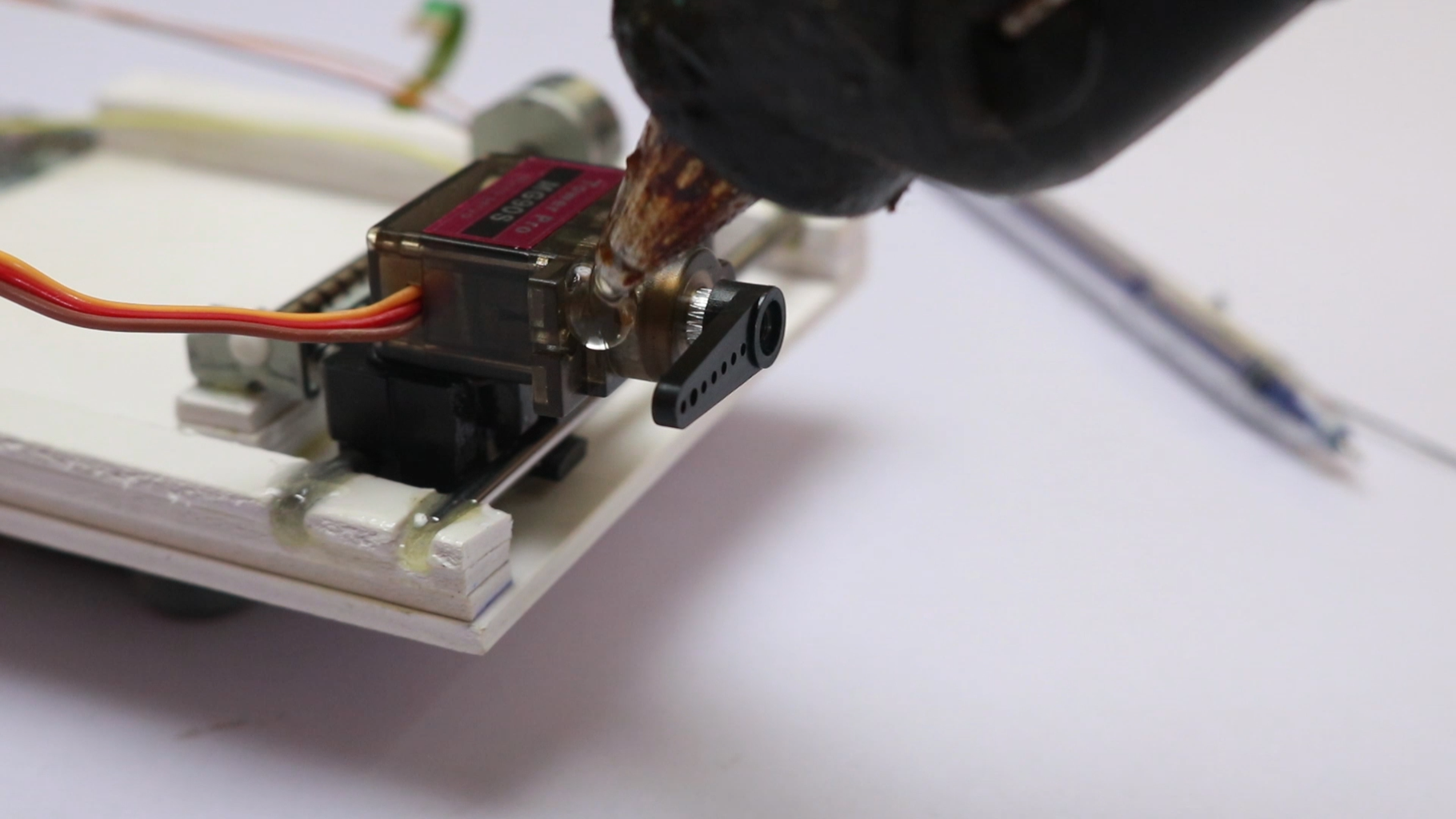

Servo Motor and Wiring

The final step in building a writing machine with hardware and electrical components is this.

From the back, insert the SG90 servo motor into the pen holder's cavity. After that, link the stepper motor wire to the two motors. Take the controller box and insert it through the bottom threaded rods of the Y-axis. Then connect the SG90 servo motor wire and the stepper motor wire to the controller box.

Firmware Installation

- Download the Corexy firmware using this link.

- https://github.com/jamescarruthers/PlotterXY

Download all of the software listed in this instructable's supply step.

Next, use a USB pin to connect an Arduino Uno to a computer. Next, launch the Arduino IDE software on your computer and choose the Arduino Uno board and Port.

Then use the file - open menu to open firmware in the Arduino IDE. then upload Arduino Uno with firmware.

Create a design in the Inkscape programme, then export it to the Universal Gcode Sender programme. then press "start" to begin writing on paper.

Writing on Paper

Fix the pen in the pen holder upside down, 4 mm from the paper. Then press "Start" to write on paper.

You can write or draw any image on this writing machine.

- Online Text to STL

- 3D Printed Soldering Helper

- 3D Printed Coin Vault

- 3D Printed FLARE GUN (PROP/REPLICA) MULTI PART

- 3D Printed Mini Container with PET Bottle Cap Size

TEST 3D PRINTS

Easy & Fun Things to 3D Print

How To Make DIY Pen Plotter / Homework Writing Machine at Home

This Drawing Robot/Pen Plotter/Drawing Machine is similar to the commercially available AxiDraw. It is powered by an Arduino Uno controller, uses a CNC Shield, and GRBL firmware.

The cost to build the Drawing Robot is between $75 and $100 depending on where you buy your parts and whether you already own some of the parts such as the Arduino.

Parts and Materials Required

- 2 x Nema 17 Stepper Motors

- 2 x Linear Rod M8 x 450mm for X Axis

- 2 x Linear Rod M8 x 350mm for Y Axis

- 2 x Linear Rod 3mm for Z Axis (you can get it from old CDROM)

- 1 x Threaded Rod M8 x 480mm

- 8 x LM8UU Bearings

- 1 x Servo Sg90

- 1 x Spring 5m (from ball point pen)

- 2 x GT2 Pulley, 16 teeth

- 5 x Bearing 624zz

- 1 x 2000mm GT2 belt

- 1 x Arduino Uno

- 1 x CNC Shield

- 2 x A4988 Stepper driver with heatsink

- 6 x Jumpers

- 1 x 12V 2A Power Supply

- 4 x 5/16in-18

- 13 x Phillips M3-0.5 x 16mm

- 4 x Phillips M3-0.5 x 6mm

- 5 x Phillips M4-0.7x 35mm

- 1 x Hex M3-0.5 x 20mm

- 4 x 5/16in washer

- 4 x M3 washers

3D Printing

- Download the files from Thingiverse

- Open the 3D models in Cura or any other slicer(Sli3er, Simplify 3D, etc.)

- Use 75% infill on all the parts (An infill of 70 – 100% will work as well)

- Printed all the parts with 0.10 – 0.20 mm layer height

- Printed with Hatchbox Red PLA

- Use supports on the Penholder, Slider, X_Support_L and the X_Support_R

Note: The longest part took around 9hrs and the shortest took 30 minutes to print

3D Printed Parts

Cut your Linear Rods

Use a measuring tape and sharpie to mark the spots where the rods need to be cut

- Use a vise to hold the rods in place when you cut them

- Remember that you need (2) 350mm and (2) 450mm long linear rods

- On the threaded rod, mark your cutting point at 470mm

Assemble the X-Axis (Linear/Threaded Rods)

Take the (2) 450mm linear rods and insert them into either x-support part

- Use may need to use a round file to smooth out the holes that you insert them in

- Also, you can use a rubber mallet to help insert the rods

Now take the threaded rod and insert it in the hole below. Feed a 5/16in washer and 5/16in nut on both sides of the x-support part

Assemble the X-Axis (Bearings)

Now you want to push the LM8UU bearings into their place on the top and bottom clamshell (The top and bottom clamshell take (4) bearings each)

Take (4) 624zz bearings and push them through the 3D-printed idler pulleys. Leave the 5th bearing for later when you assemble the Y-axis

Assemble the X-Axis (Carriage)

- Get (4) M3-0.5 x 20mm screws, (4) M3 nuts, (4) M3 washers and (4) 624zz bearings with the idler pulleys installed

- Take one screw and feed a washer through it, the washer will rest on the bearing. The nut will be at the bottom of the carriage, which will secure the bearing in place

Assemble the X-Axis (X-Support)

- Slide the clamshell through the 450mm (X-axis) linear rods

- Use a rubber mallet again to attach the last X-support on the linear rods

- Make sure that the rods stick out equally on both sides

- Slide the other end of the threaded rod through the hole on the X-support

- Put on the last set of nuts and washers to hold the X-support in place

- Now that the X-axis is complete, you can use (2) Phillips M3-0.5 x 16mm screws per X-support to help keep the linear rods from sliding

Assemble the X-Axis (Stepper Motors)

- Use an appropriate sized allen wrench to attach the 16 teeth pulleys on the stepper motor shafts

- Flipping the entire chassis around will make it easier to attach the stepper motors

- Use (8) M3-0.5 x 6mm screws and a Phillips screwdriver to attach the (2) stepper motors

Assemble the Y-Axis (Clamshell)

(Optional if you have problems keeping belt on bearings)

- Grab (4) M4-0.5 x 35mm screws and (4) M4 nuts

- Make sure that you have the (4) idler pulleys ( Download from Thingiversa ) and the (4) washers printed

- Insert the washers in between the two clamshells, with a screw in between

- Screw the top and bottom clamshells together

Assemble the Y-Axis (Y- Back/Front)

- Take the (2) 350mm linear rods and insert them the Y-back piece by using a rubber mallet

- Get (1) M4-0.5 x 35 screw, (1) M4 nut and the 5th 624zz bearing

- Get (2) M3-0.5 x 16 screws to secure the linear rods

- Slide in the bearing when inserting the screw through the Y-back piece

- Slide the the linear rods/Y-back piece through the LM8UU bearings and attach the Y-front piece using a rubber mallet

Assemble the X-Y Axis (Belt)

- Use a pair of needle nose pliers to help guide the GT2 belt more easily through the clamshell

- Take the two ends of the belt and slide them through the “teeth” on the Base Slider

- The belt should be tight and not loose

- Note that once the GT2 belt is on, it is normal for the clamshell not to move easily

Belt Diagram

Assemble the Z-Axis

- Get (2) 3mm linear rods and the following 3D printed parts (Slider, Pen Holder, Base Slide, 3MM Metric Thumb Screw)

- Get (1) Hex M3-0.5 x 20mm screw and the Metric Thumb Screw and push them together. Use superglue to keep it together.

- Get (3) M3-0.5 x 16mm screws which you will use the secure the Base Slide to the Y-Front part. You may need to use (3) M3-0.5 nuts in order to hold it in place

- Push the Slider and Pen Holder together to make one piece

- Now take that new part and the (2) 3mm linear rods and slide the rods through the holes. Place a small spring in between the two parts so there is a little bit of pressure to lift the Slider. You may need to cut the spring a bit until there is an adequate amount of pressure on the slider.

Step By Step Video

The Original Instructions by Henry Arnold Jonathan K

- 3D Printed Hairy Lion →

12 thoughts on “ How To Make DIY Pen Plotter / Homework Writing Machine at Home ”

i constructed all the machine but when i press X+ the both X and Y axis are moving what is the problem

double check the steppers wiring

Have you solved it? I have the same problem with my machine, when I press X+, it’s necessary both motors move at same time, but, only one of them move…

Did you solve this problem?

Same problem how to solve ,?

Is it true that you didn’t use the microswitches in the final design?

Hello how to co figurę this machine to RUN on GRBL. What I mean is that GRBL interprets commands for x axis and y axis independently and if I look on your belt diagram it looks like both Motors have to run at the same time in order to move the carriage along y axis… How did you do that?

Have you solved it?

Thank you, thank you. It’s a very good built.

Is it possible to modify it to draw using brush ang oil based paint ?

Could you please tell what software/plug in and which version do you use to generate g-code for this machine?

Hello, what is the width of your belt? 6mm or 10mm? Thanks!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

News the global electronics community can trust

The trusted news source for power-conscious design engineers

Supply chain news for the electronics industry

The can't-miss forum engineers and hobbyists

The electronic components resource for engineers and purchasers

Design engineer' search engine for electronic components

Product news that empowers design decisions

The educational resource for the global engineering community

The learning center for future and novice engineers

The design site for electronics engineers and engineering managers

Where makers and hobbyists share projects

The design site for hardware software, and firmware engineers

Where electronics engineers discover the latest tools

Hardware design made easy

Brings you all the tools to tackle projects big and small - combining real-world components with online collaboration

Circuit simulation made easy

A free online environment where users can create, edit, and share electrical schematics, or convert between popular file formats like Eagle, Altium, and OrCAD.

Transform your product pages with embeddable schematic, simulation, and 3D content modules while providing interactive user experiences for your customers.

Find the IoT board you’ve been searching for using this interactive solution space to help you visualize the product selection process and showcase important trade-off decisions.

A worldwide innovation hub servicing component manufacturers and distributors with unique marketing solutions

SiliconExpert provides engineers with the data and insight they need to remove risk from the supply chain.

Transim powers many of the tools engineers use every day on manufacturers' websites and can develop solutions for any company.

Search EEWeb

- Newsletters

- Internal/External

- Embedded Microstrip

- Symmetric Stripline

- Asymmetric Stripline

- Wire Microstrip

- Wire Stripline

- Edge-Coupled Microstrip

- Edge-Coupled Stripline

- Broadside Coupled Stripline

- Twisted Pair

- RF Unit Converter

- Online SPICE Simulator

- Schematic Converter/Viewer

- Schematic Capture Tool

- Standard Values

- Magnetic Field Calculator

- Wire Self Inductance

- Parallel Wires

- Wire over Plane

- Rectangle Loop

- Broadside-Coupled Traces

- Edge-Coupled Traces

- Engineering Paper (Printable PDF)

- Log-Log Graph Paper (PDF Download)

- Semi-Log Graph Paper (PDF Download)

- Smith Chart Graph Paper (PDF Download)

- Math Reference Sheets Overview

- Algebra Reference Sheet

- Geometry Reference Sheet

- Trigonometry Definitions and Functions

- Trigonometry Rules, Laws, and Identities

- Calculus Derivatives, Rules, and Limits

- Calculus Integrals Reference Sheet

- Online Basic Calculator

- Scientific Calculator

- Tech Communities

- Analog Design

- Power Design

- Digital Design

- Embedded Systems

- Test & Measurement

- Electromechanical

- Passive Components

- Design Library

- Extreme Circuits

- Magazines Archive

- Design Contest

- Homework Writing Machine

This homework writing machine project features a DIY writing machine that uses a typical pen. It can do outline writing and digital signature or even a real text. The main system uses a 2 axis stepper motor driver board with Nema stepper motors and Mg90S Metal Gear Servo control.

The 2 axis stepper motor driver board serves as the main controller. It organizes the motor drivers connection that best fit for the writing machine operation. This writing machine uses threaded rod rotated by nema 17 stepper motors for X-axis and Y-axis movements on the surface, while a Mg90S metal gear servo is used in the pen stand that moves the pen perpendicular to the writing surface. The movements of the motor are synchronized and quite accurate provided that it is assisted by a well-made writing machine frame structure with mixed of wood and acrylic materials.

This project is suitable for embedded development hence it can accomplished digital writing activity. It is also a good reference for DIY text and figure printing provided that it can draw specific figures.

Sources: How to Make Homework Writing Machine at home

Other Related Topics

- Building an Audio-Reactive Music Box

- Go Kart / Electric Car using PVC Pipe

Join the Conversation!

One reply to “homework writing machine”.

sir I am a student of MS electrical power engineering and my thesis are just close to starting but I am confused about topic selection. my area of interest is RENEWABLE ENERGY TECHNOLOGY. please sir help me in topic selection

Add Comment Cancel reply

You must be logged in to post a comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- FarhnSh1d 2024-04-03 02:40:00 1. Energy Source Availability: Identify available energy sources such as solar, wind, vibration, thermal gradients, or ambient RF signals. Choose a technology capable of effectively capturing and converting this energy into usable electrical power. 2. Energy Density and Power Output: Assess the energy density and power output of each potential source to determine if it can meet the application's power requirements, considering factors like sensor power consumption and duty cycle. 3. Environmental Conditions: Evaluate the environmental conditions of the remote location, including temperature extremes, humidity, and exposure to elements. Choose a technology that can withstand these conditions and operate reliably...

- FarhnSh1d 2024-04-03 02:39:02 Reducing the output power of an ultrasonic Piezo Ceramic disc from 35 watts to 10 watts by adjusting the control board is possible but entails several considerations: Effectiveness and Performance Lowering power may compromise the effectiveness of the ultrasonic device, potentially reducing its ability to achieve desired results like cleaning or atomization. Reduced power might lead to weaker vibrations, impacting performance, especially if the device operates away from its optimal resonance frequency. Durability and Lifespan Lowering power could potentially increase the device's lifespan by reducing stress on the piezo ceramic disc. However, extreme power reductions may lead to inadequate vibrations...

- forlinxembedded 2024-03-21 04:05:55 Hello Erdem, It's interesting to learn about the differences in electric pole usage between countries. In many countries, wooden poles are commonly used due to their availability, cost-effectiveness, and ease of installation. However, in regions with higher load requirements like Turkey, stronger poles are necessary to support the infrastructure. In the USA and some European countries, wooden poles are reinforced and treated to withstand the required loads. Additionally, alternative materials like steel and concrete are also used for electric poles in various applications. If you're interested in learning more about electric pole types and standards in different countries, I recommend...

- Lumispot 2024-03-04 11:00:10 Microcontroller For a project like yours, the choice of a microcontroller (MCU) largely depends on the complexity of the device, the number of input/output peripherals you need (like GPIOs for the sensor, speaker, LED lights, and the green light indicator), and any additional features you might require (such as PWM outputs for LED dimming or speaker volume control). Arduino Uno is a robust choice for beginners and prototypes. It's based on the ATmega328P and offers a good balance of GPIO pins, is easy to program, and has extensive community support. Arduino Nano or Arduino Micro could be more suitable for...

- richard-gabric 2024-03-04 11:00:01 You are setting yourself up to kill yourself, or at least to take an eye out. You don't say what DC voltage you need, the voltage you would get from directly applying the mains to a bridge rectifier were typically used, for example, to supply the input to a flyback switch mode power supply, where the switching transformer provides mains isolation. The voltage would typically be around 300V DC, and the rectifier and capacitors have to be rated for that voltage plus a safety factor. I assume that you are needing a low voltage DC, since you have 25Vdc capacitors...

- suvsystemltd 2024-03-01 09:15:42 one suitable device is the LTC4371 from Analog Devices. The LTC4371 is an automotive-grade ideal diode controller designed to operate in harsh environments, making it compliant with the AEC-Q100 standard. Key features of the LTC4371 include: Input Voltage Range: The LTC4371 typically operates with an input voltage range that covers your specified 2.5V requirement. AEC-Q100 Qualification: The LTC4371 is qualified for automotive applications, meeting the AEC-Q100 standard. This ensures reliability and performance under automotive operating conditions. Ideal Diode Functionality: The LTC4371 is specifically designed as an ideal diode/OR-ing controller. It allows for seamless power source transition and provides a low-loss...

- AdeZep 2024-02-23 07:14:54 74AC14 willl do the job ? Thanks!...

- ViasionTech 2024-02-13 09:30:44 In the USA and parts of the EU, wooden electric transmission poles are commonly used due to their cost-effectiveness, widespread availability, and environmental friendliness. The decision is influenced by regional engineering standards, emphasizing factors like renewable resources and biodegradability. While wooden poles may have lower load-bearing capacity than those used in Turkey, they meet safety requirements for specific voltage and environmental conditions. To obtain detailed information about electric pole types and standards in a specific country, it is advisable to contact local electric utilities, government agencies, or industry associations for relevant documentation or standards....

Browse by Categories

- Digital Design (1)

- Electromechanical (15)

- Embedded Systems (51)

- Featured (117)

- General (15)

- Power Design (13)

- RF Design (5)

- Sensors (12)

- Standard (4)

- Test & Measurement (3)

Browse by Topics

- Arduino (28)

- Electronics (9)

- Microcontrollers (10)

- Raspberry Pi (9)

- Robotics (15)

- Wireless (9)

- List of Topics

Homework Writing Machine

Introduction: Homework Writing Machine

DOWNLOAD OUR NEW APPLICATION TO GET ALL SCIENCE DIY PROJECTS AT ONE PLACE.TO DOWNLOAD CLICK BELOW.

CLICK HERE >>>>>> DIY PROJECTS

Hi guys , As per the title this is a simple project using Arduino to make Homework writing machine at your home.This machine can draw any design and write any type of fonts.You can see sharpness and perfection of writing in photos.

If you are looking for more Arduino Projects ideas than writing machine is the best projects for Arduino projects.

Step 1: Watch Youtube Video of Making Writing Machine

Here is full video of how writing machine is work on surface.If You Like This Project Please Press The Like Button.

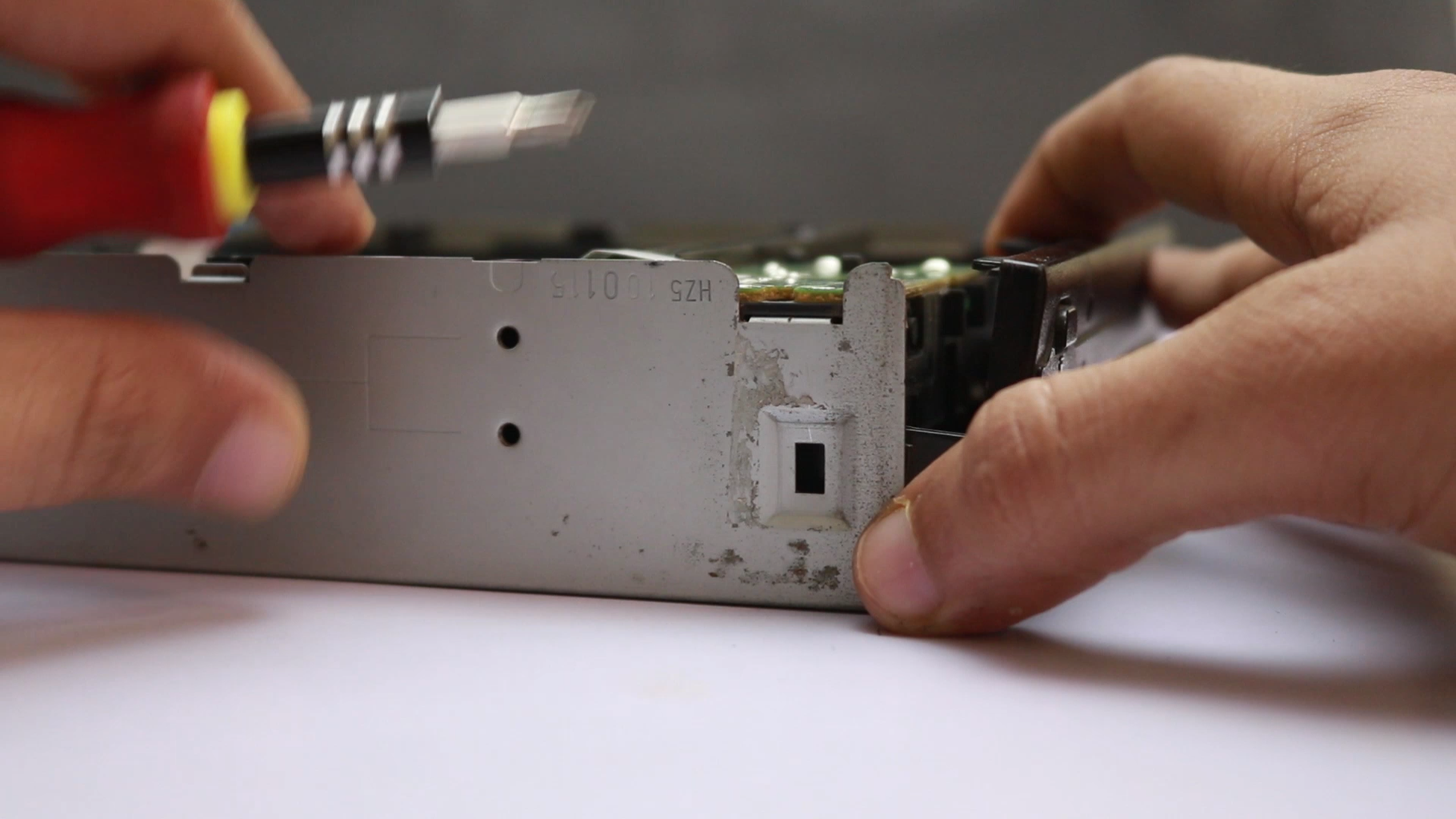

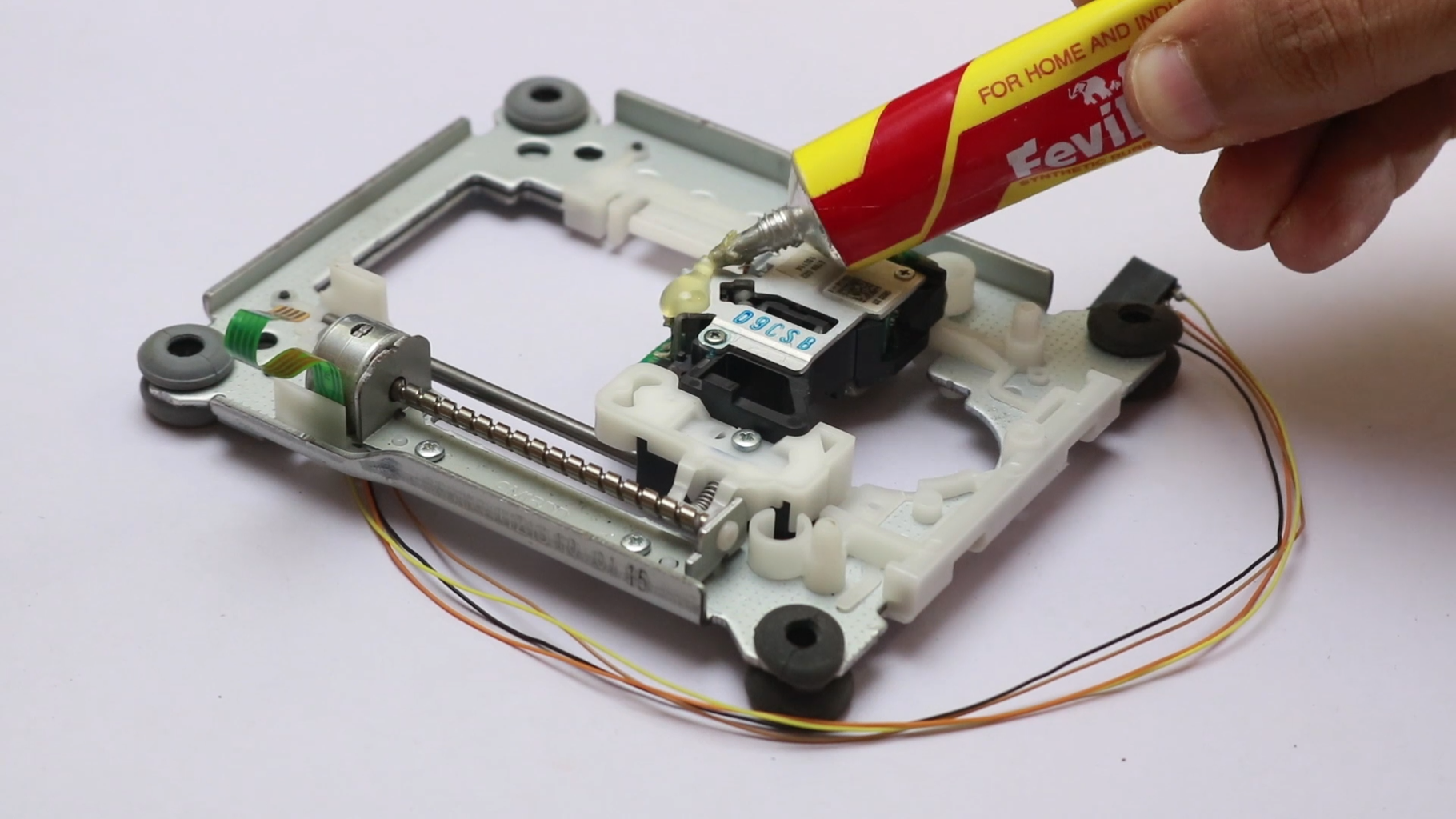

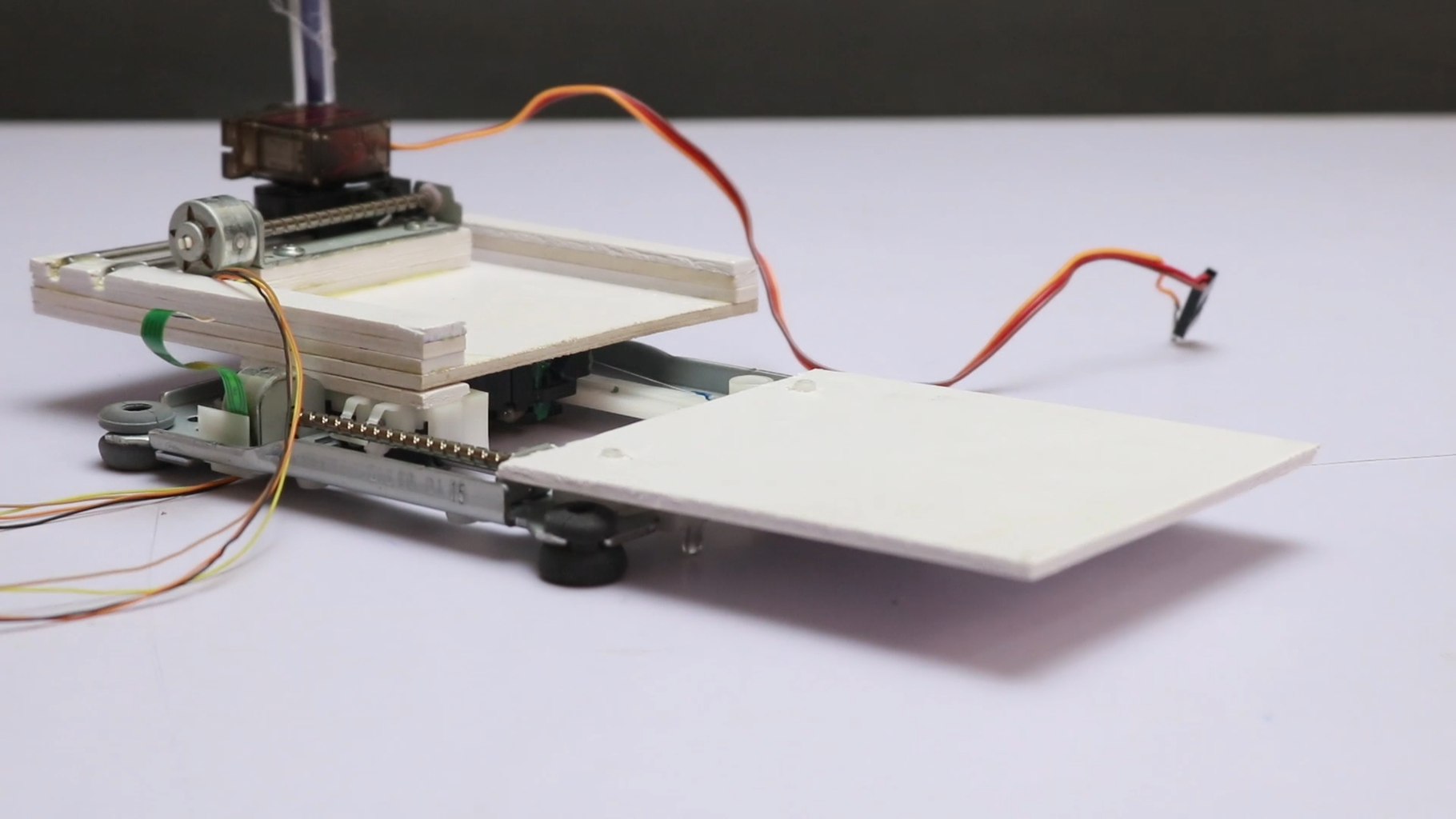

Step 2: Disassemble DVD Writers.

First of all you need 2 DVD writers of your CPU.You can use non workable DVD writer for this project.

Take 2 DVD writers and open 5 screw on bottom of this DVD writer. Then open bottom case of DVD writer and disconnect all circuit.

Then open Top case of DVD writer.

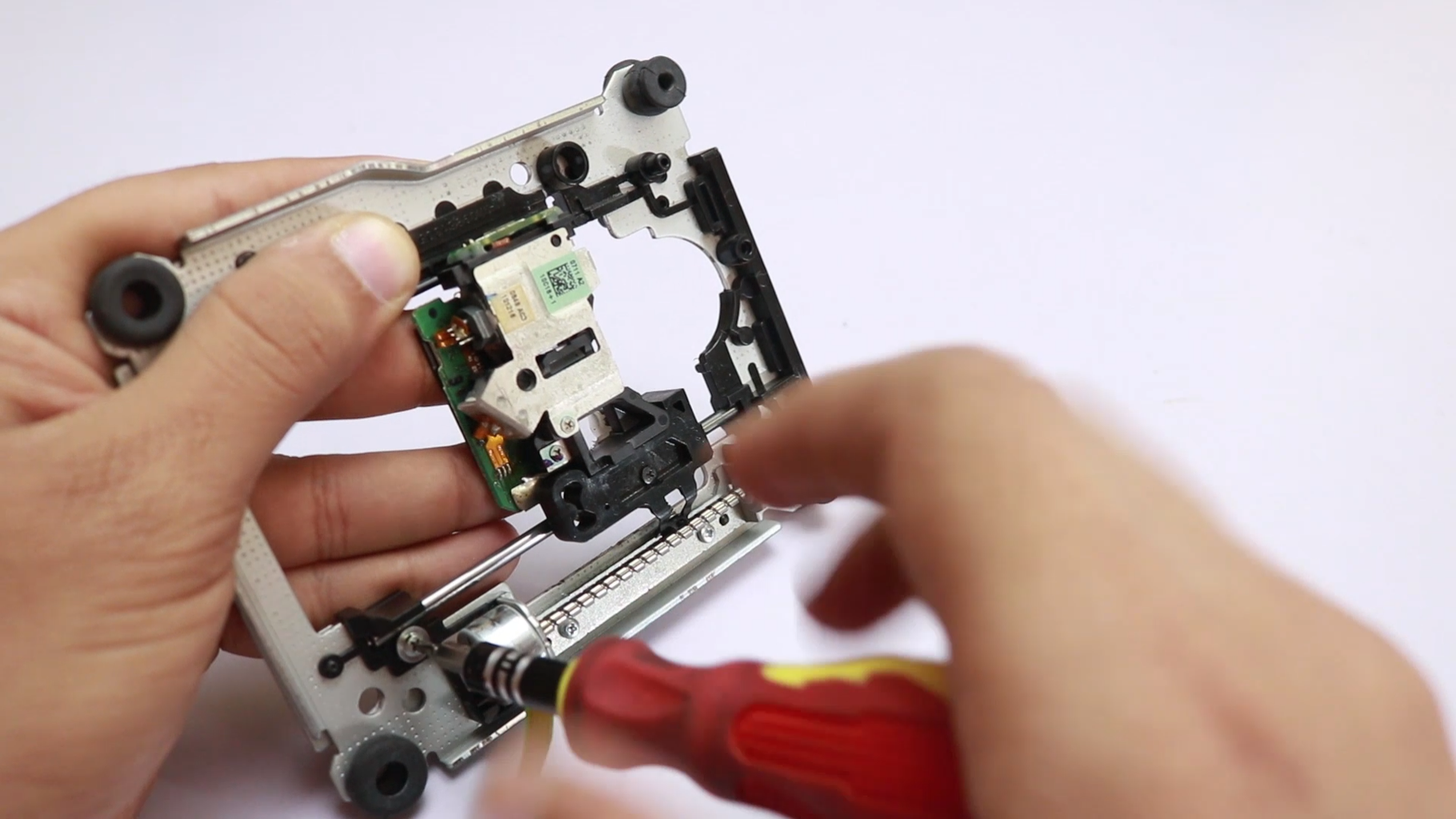

Step 3: Disassemble All Parts.

After this you see rectangle part of DVD writer with stepper motor on back side. Open 2 screw on this Rectangle and remove this rectangle outside.

Repeat this process for 2nd DVD writer.

After this you have two PCs of Rectangle Part (AS per 2nd Pic.)

Step 4: Unscrew Stepper Motor

Open one screw on sliding shaft and 2 screw on stepper motor.

Disassemble stepper motor and sliding parts from one rectangle.

Remove all circuit of sliding part and cut middle part of this sliding part.

Now you have 2 PCs of plastic part.Combine both plastic object and stick with FeviQuik.

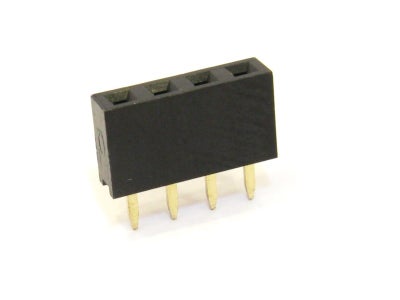

Step 5: Connection of Stepper Motor

Take female header pin (4 pin) as a picture.

Connect two stepper motor with this 4 pin female header as show in picture(In the same line).

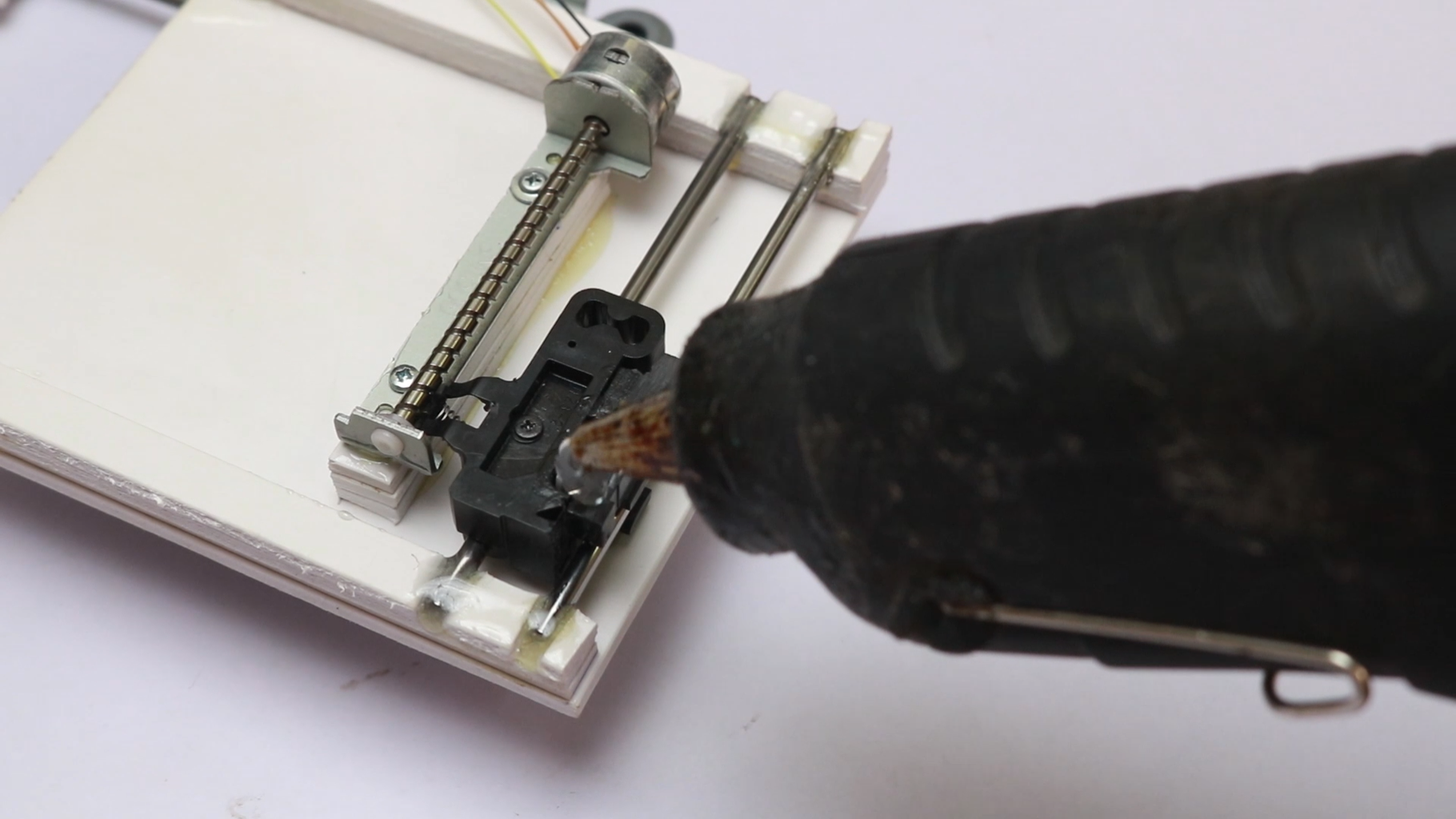

Step 6: Make X - Axes Gantry.

Take Sunboard sheet of 10 cm length and 9 cm width.

Take other sunboard sheet and cut this type of object.

1) 3 x ( 1cm x 10cm) combine with glue.

2) 3 x ( 1cm x 10cm) combine with glue.

3) 3 x ( 1cm x 5 cm ) combine with glue.

Stick 1st part on left side of 9x10cm sunboard sheet and 2nd part on right side of 9x10cm sunboard sheet.

Place shifting part on this sunboard sheet along X axes.

And your X axes Gantry is ready.

Sick 3rd part Parallel to shifting shaft and Stick Stepper motor with X axes Gantry.

Step 7: Connect With Y - Axes Gantry.

Step 8: Connect Servo Motor.

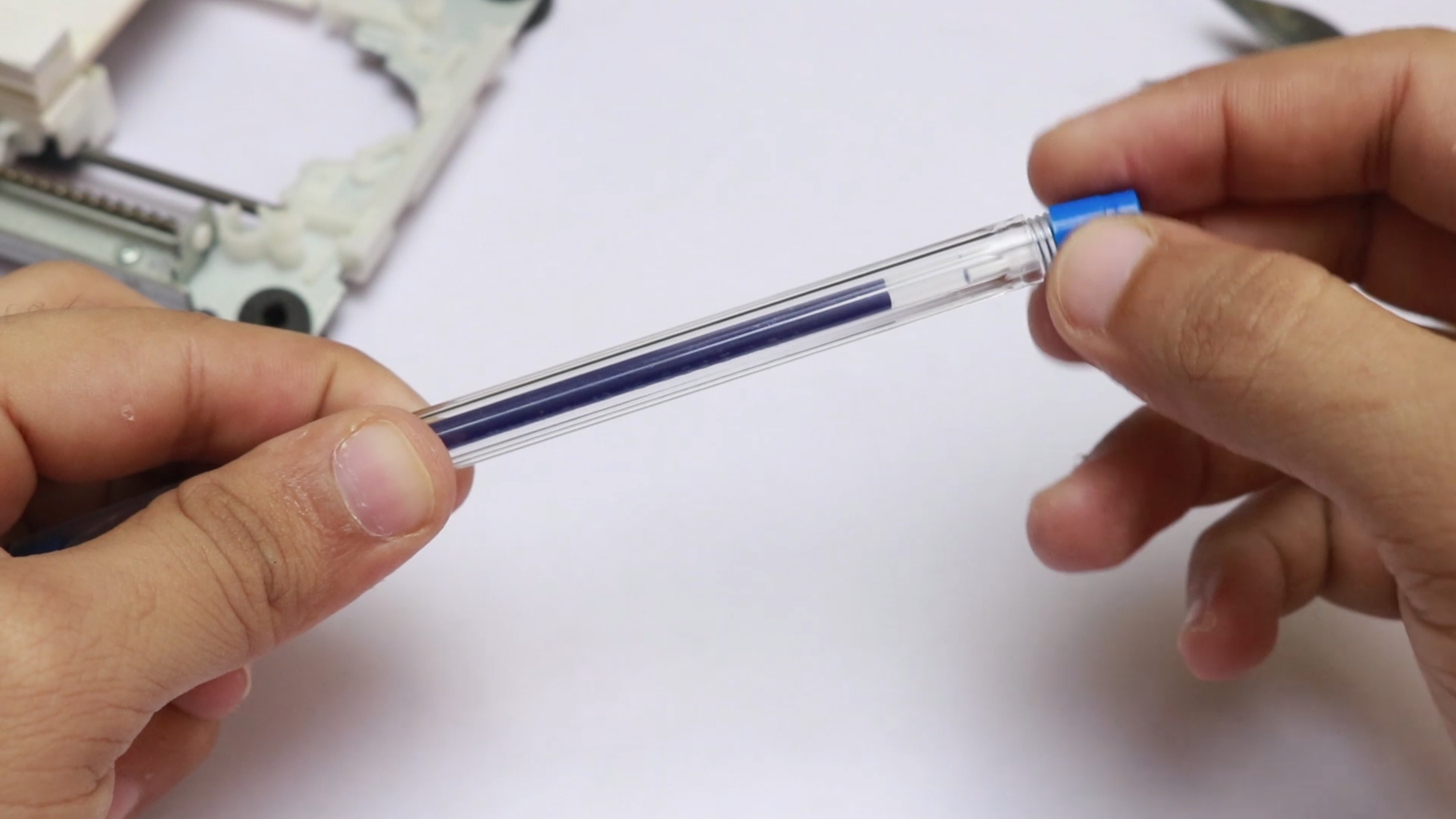

Step 9: Flexible-nib Pen Making

Step 10: Connect Pen

Step 11: Take All Circuit

Ready your all circuit. 1) 2 PCs A4988 Stepper Motor Driver with heat sink

2)Expansion Board A4988 Driver

3)Arduino Uno R3

First of all take hit sink and stick on A4988 stepper motor Driver.

2 PCs A4988 Stepper Motor Driver connect on Expansion Board A4988 Driver module. Then this combination connect on Arduino Uno R3 (As per circuit Diagram).

Step 12: Wiring

Step 13: Benbox Softwer Configuration.

Step 14: Watch This on Youtube.

IF YOU LIKE THIS PROJECT PLEASE VOTE ! VOTE ! VOTE ! IN CONTEST.

Step 15: Any Error !

If you have any questions about this project please comment in comment section.If you made this writing machine and any error during writing please attach your writing machine pictures.I will reply very soon.

IMAGES

VIDEO

COMMENTS

To design this writing instrument, I used Autodesk Fusion 360. There are many different kinds of writing robots, but in this lesson, I create a corexy writing machine. Making use of this will teach you everything there is to know about this writing robot. All of the 3D printed parts are attached stages in the .stl file.

Hi, in this blog I will show you how to make your own homework writing machine also known as 2d plotter. This machine can write on any surface using any type of pen, pencil, sketch pen or marker. This is useful when you have to complete an assignment or draw beautiful and neat diagrams for your school/college project to fetch those extra marks.

Introduction: Make DIY Homework Writing Machine at Home. ... then connect the arduino with expansion board and connect all wiring The shield also has a built-in micro stepping control - meaning that instead of using full steps or half steps like a large CNC would do, we can make the motors move by 1/16 or 1/32 of a step to make the laser move ...

Make DIY Homework Writing Machine at Home: Drawing Robot/Pen Plotter/Drawing Machine is an Open Hardware version of the famous machine AxiDraw which it is a pen plotter, capable of writing or drawing on almost any flat surface. ... If there's resistance between the two wires, you have a coil. On the schematic, the coils are represented by two ...

Make a Homemade Homework Writing Machine. April 6, 2022. by pondabrothers. 7 min read. ... Prepared for your whole circuit. 1) A4988 Stepper Motor Driver, 4 pcs 2) A4988 Expansion Board Driver ... The coils are represented on the diagram by two wires of the same colour. Step 9: APPLICATION SOFTWARE.

by akashv44 in Circuits > Robots. 26517 Views, 342 Favorites, 0 Comments DIY Homework Writing Machine. In this Instructable, I'll show you how to create a completely functional 3D-printed writing machine for your science fair project at school or college. This project was created as part of my second-year engineering project at Gujarat's ...

This Drawing Robot/Pen Plotter/Drawing Machine is similar to the commercially available AxiDraw. It is powered by an Arduino Uno controller, uses a CNC Shield, and GRBL firmware. The cost to build the Drawing Robot is between $75 and $100 depending on where you buy your parts and whether you already own some of the parts such as the Arduino.

Circuit simulation made easy. A free online environment where users can create, edit, and share electrical schematics, or convert between popular file formats like Eagle, Altium, and OrCAD. ... This homework writing machine project features a DIY writing machine that uses a typical pen. It can do outline writing and digital signature or even a ...

Make Diy Homework Writing Machine At Home. ... Its unique design features a writing head that extends beyond the machine, making it possible to draw on objects bigger than the machine itself. ... On the schematic, the coils are represented by two wires of the same color. Step 9: SOFTWARE. 1 / 8. Inkscape which is the graphics design software ...

Homework Writing Machine: DOWNLOAD OUR NEW APPLICATION TO GET ALL SCIENCE DIY PROJECTS AT ONE PLACE.TO DOWNLOAD CLICK BELOW. ... Then open bottom case of DVD writer and disconnect all circuit. Then open Top case of DVD writer. Step 3: Disassemble All Parts. ... (As per circuit Diagram). Step 12: Wiring. Step 13: Benbox Softwer Configuration ...